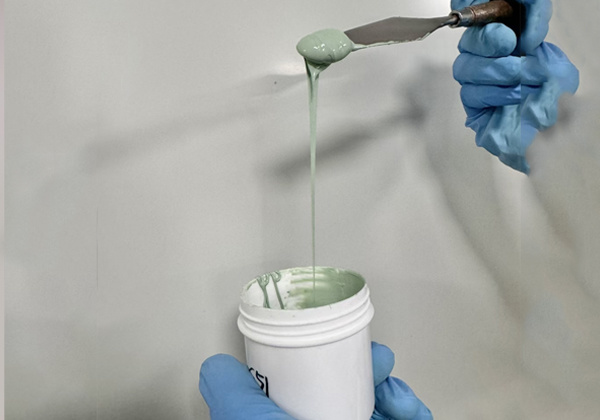

Glass paste is a product used for bonding various metals, ceramics, and chips.

Glass paste is a thick-film resistor printing glass paste that complies with RoHS standards. After sintering, the paste turns pale green and becomes transparent, exhibiting excellent adhesion, outstanding acid and water resistance, as well as superior sulfur resistance.

This product can form a glass glaze layer on electronic ceramic substrates, making it ideal for extreme environments such as wafer electrostatic chucks—environments characterized by high temperatures and high electrical resistance. It effectively increases the substrate's insulation resistance, enhances adhesion between precious metal pastes, and ensures no deformation during sintering, while maintaining long-term durability even at temperatures as high as 1000°C.

This product is designed for printing a protective glass glaze layer onto circuit boards, safeguarding circuits from environmental erosion that could otherwise lead to reduced resistance. It is typically used in conjunction with GCE401 paste, providing protection for substrates and other components.

This product is suitable for thick-film circuits and chip resistor applications, often used in conjunction with GCE401 paste to protect substrates, base glazes, and printed circuits.